Cosmetics Manufacturing Advances: Cutting-Edge Technology

Cosmetics companies are always looking for a competitive edge, and one of the best ways to make a product stand out is to use advanced manufacturing technology. The latest advances allow cosmetic products to be produced with heightened accuracy and quality, resulting in a final product with better efficacy and a longer shelf-life.

By utilizing these technologies, businesses have seen an increased success rate in their product launches, which have resulted in improved customer satisfaction scores and, ultimately, higher profits.

Today, the advancement of cosmetics manufacturing technology continues to make breakthroughs, pushing the limits of what is achievable when producing skincare, makeup and beauty items. Read on to learn more about the current technological advancements and the positive effects they have on the cosmetics manufacturing industry.

The Industry Benefits of Advanced Cosmetics Manufacturing Technology

The cosmetics industry is always striving for more efficient production methods, and advanced manufacturing technologies are making these efforts a reality. By integrating the latest and most efficient technological advances into the production process, businesses can achieve a number of valuable benefits:

-

- Faster production cycles

-

- Reduced waste

-

- Consistent product quality

-

- Higher customer satisfaction scores

-

- Decreased risk of product defects

- Increased profitability

These advancements are vitally important to businesses in the cosmetics industry, as they save time and money while delivering a product of the utmost quality and effectiveness. Below, we discuss some of the current technological advances that have revolutionized the cosmetics manufacturing industry.

The Latest Advanced Technology in Cosmetic Manufacturing

The rapid progression of technology has changed the face of cosmetic manufacturing. With the right equipment and new methods of production, businesses in this industry can experience significant changes in their production lines. Here are some of the most notable technological advances in cosmetics manufacturing:

Precision Robot Knife Technology

Robotics are being used to add more accuracy to the slicing process. FANUC’s Automated Blade Setting solution uses a robot to accurately slice through materials for cosmetic products, replacing the more expensive and less precise manual method. This technology increases the production speed and accuracy, allowing for higher product quality as minimal waste.

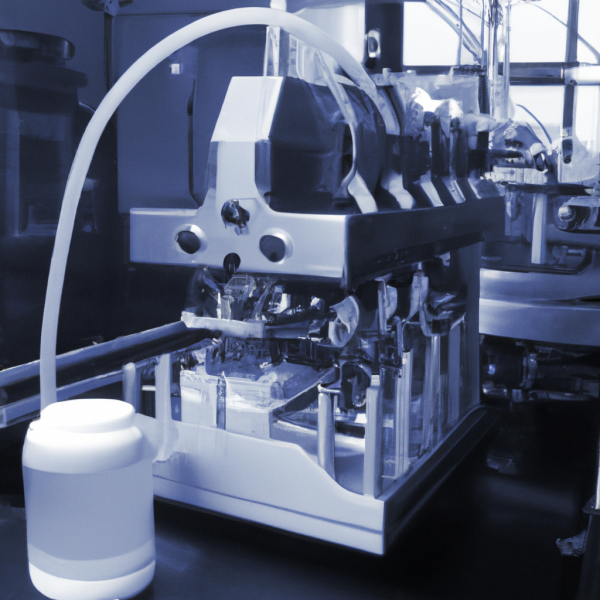

Advanced Mixing Technology

Advanced mixing technology is allowing for improved batch-to-batch consistency when producing cosmetics. With the appropriate technologies, businesses can mix together batch ingredients with greater accuracy, making it easier to produce consistent results.

Intelligent Control Solutions

The addition of sensors and other intelligent controls can help to ensure accuracy and efficiency when dealing with cosmetic ingredients. By tracking ingredient levels, speeds and other variables, businesses can operate with greater precision and accuracy with fewer errors.

FAQs about Advanced Cosmetics Manufacturing Technology

What are the benefits of advanced cosmetics manufacturing technology?

The benefits of advanced cosmetics manufacturing technology include faster production cycles, reduced waste, consistent product quality, higher customer satisfaction scores, decreased risk of product defects and increased profitability.

What is the most recent advanced technology in cosmetics manufacturing?

Some of the most recent advanced technologies in cosmetics manufacturing include precision robot knife technology, advanced mixing technology and intelligent control solutions.

How is advanced technology changing the production of cosmetics?

Advanced technologies are making the production of cosmetics faster and more accurate, leading to improved product quality and less waste. It is also helping businesses increase their profitability, as these technologies reduce needed man-hours and create more reliable products.

Optimizing Cosmetics Manufacturing with Advanced Technology

Cosmetics manufacturing has witnessed remarkable advancements in recent years, thanks to cutting-edge technology. By leveraging these technological breakthroughs, cosmetic companies have been able to enhance the accuracy, quality, and overall efficacy of their products. In turn, this has led to improved customer satisfaction, increased success rates for product launches, and ultimately, higher profitability.

Benefits of Advanced Cosmetics Manufacturing Technology

The integration of advanced manufacturing technologies into the cosmetics industry has unlocked numerous benefits for businesses. These benefits include:

- Faster production cycles: Advanced technology enables streamlined processes, resulting in faster production cycles.

- Reduced waste: By leveraging efficient manufacturing techniques, businesses can minimize waste and optimize resource utilization.

- Consistent product quality: With the help of advanced technology, cosmetic manufacturers can ensure consistent quality across their product lines.

- Higher customer satisfaction scores: Improved product quality and efficacy contribute to higher customer satisfaction, leading to increased brand loyalty.

- Decreased risk of product defects: Advanced manufacturing technologies help mitigate the risk of defects, ensuring that products meet stringent quality standards.

- Increased profitability: By enhancing efficiency, reducing costs, and delivering high-quality products, businesses can experience significant improvements in profitability.

These advantages are crucial for cosmetics companies aiming to stay competitive and deliver exceptional products to their customers. Now, let’s delve into some of the latest technological advancements that have revolutionized cosmetics manufacturing.

Revolutionary Technological Advances in Cosmetic Manufacturing

Precision Robot Knife Technology

Robotic automation has significantly improved the slicing process in cosmetic manufacturing. One notable solution is FANUC’s Automated Blade Setting, which employs robots to precisely slice through materials for cosmetic products. This technology replaces manual methods that are often less precise and more expensive. By using robotic systems, cosmetic manufacturers can achieve faster production speeds, unparalleled accuracy, and minimal waste, resulting in higher product quality.

Advanced Mixing Technology

The advent of advanced mixing technology has revolutionized batch-to-batch consistency in cosmetic production. With sophisticated equipment and processes, businesses can now achieve precise ingredient mixing, leading to more consistent results. This technology ensures that each batch meets the desired quality standards, resulting in reliable and effective cosmetic products.

Intelligent Control Solutions

The incorporation of sensors and intelligent control systems has transformed the manufacturing landscape for cosmetic ingredients. By monitoring crucial variables such as ingredient levels and speeds, businesses can operate with enhanced precision, accuracy, and efficiency. These intelligent control solutions reduce the likelihood of errors and ensure that cosmetic products are manufactured to the highest standards.

Frequently Asked Questions about Advanced Cosmetics Manufacturing Technology

Q: What are the benefits of advanced cosmetics manufacturing technology?

A: Advanced cosmetics manufacturing technology brings forth numerous benefits, including faster production cycles, reduced waste, consistent product quality, higher customer satisfaction scores, decreased risk of product defects, and increased profitability.

Q: What is the most recent advanced technology in cosmetics manufacturing?

A: Some of the latest advanced technologies in cosmetics manufacturing include precision robot knife technology, advanced mixing technology, and intelligent control solutions.

Q: How is advanced technology changing the production of cosmetics?

A: Advanced technologies are revolutionizing cosmetic production by making it faster, more accurate, and more efficient. They contribute to improved product quality, reduced waste, increased profitability, and a streamlined manufacturing process that requires fewer man-hours

.

In conclusion, the integration of advanced technology in cosmetics manufacturing is propelling the industry forward. By leveraging precision robot knife technology, advanced mixing techniques, and intelligent control solutions, businesses can optimize their production processes, achieve consistent quality, and deliver exceptional products that cater to evolving consumer demands. Embracing these technological advancements is crucial for cosmetic companies striving to stay ahead of the competition and unlock the full potential of their manufacturing capabilities.